Contributing to a viable future

Scalable, modular electrolyser systems

(multi-core) for the world’s middle-market

(multi-core) for the world’s middle-market

At XINTC we manufacture premium quality, innovative electrolyser systems that meet the needs of our customer base. Our people are driven by motivation to design products that minimize the total cost of ownership.

Scalable, modular electrolyser systems (multi-core) for the world’s middle-market

Contributing to a viable future

At XINTC we manufacture premium quality, innovative electrolyser systems that meet the needs of our customer base. Our people are driven by motivation to design products that minimize the total cost of ownership.

A flexible, modular approach, conceived to serve both smaller and larger production capacity demands, scaling with evolving business practices

A flexible, modular approach, conceived to serve both smaller and larger production capacity demands, scaling with evolving business practices

By using technical plastics and a sophisticated assembly technique, the electrolyser module is liquid- and gas-tight, which enhances intrinsic safety. Each set is equipped with control electronics (Module Management Control) for optimal process control and monitoring. De facto, the electronics direct each individual module to its best possible operating point in terms of gas production and efficiency, regardless of load.

XINTC develops, produces and markets scalable, modular electrolyser systems (multi-core) for the global middle-market

XINTC develops, produces and markets scalable, modular electrolyser systems (multi-core) for the global middle-market

By using technical plastics and a sophisticated assembly technique, the electrolyser module is liquid- and gas-tight, which enhances intrinsic safety. Each set is equipped with control electronics (Module Management Control) for optimal process control and monitoring. De facto, the electronics direct each individual module to its best possible operating point in terms of gas production and efficiency, regardless of load.

A perfect product-market fit

FLEXIBLE POWER SUPPLY

Multiple (intermitting) power sources, full dynamic operation

SCALABLE CAPACITY

Thoughtfull product architecture, smooth assembly with distinct functional units

LOW MAINTENANCE

Little wear parts,

long running time components,

automated process control,

no critical materials

FLEXIBLE USE

Numerous application, varying hydrogen quality and output pressure

SMART ELECTRONICS

Both individually and collectively controlled electrolyser modules, high system security

A perfect product-market fit

FLEXIBLE POWER SUPPLY

Multiple (intermitting) power sources,

full dynamic operation

SCALABLE CAPACITY

Thoughtfull product architecture, smooth assembly

with distinct functional units

LOW MAINTENANCE

Little wear parts, long running time

components, automated process control,

no critical materials

FLEXIBLE USE

Numerous application, varying hydrogen quality

and output pressure

SMART ELECTRONICS

Both individually and collectively controlled electrolyser modules, high system security

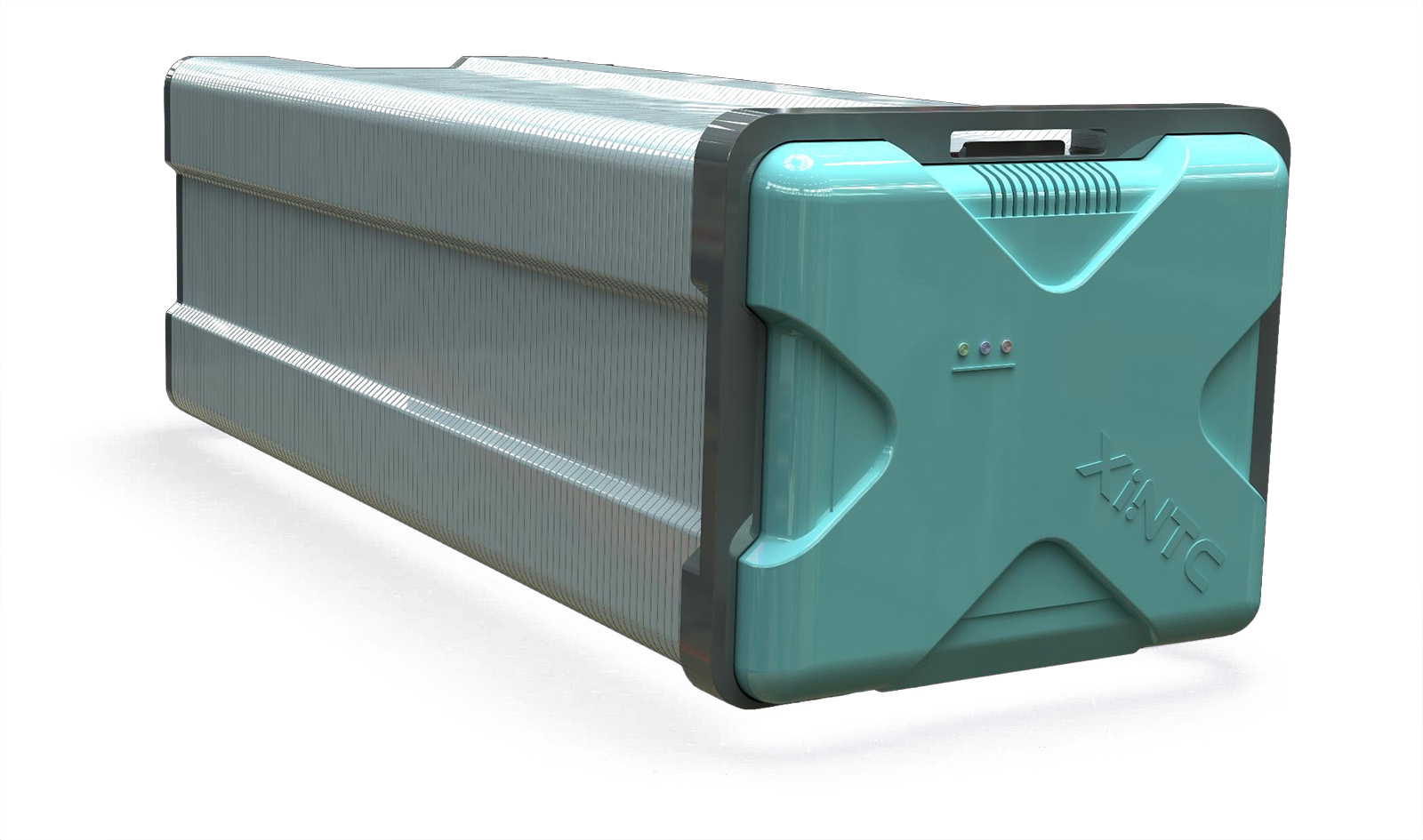

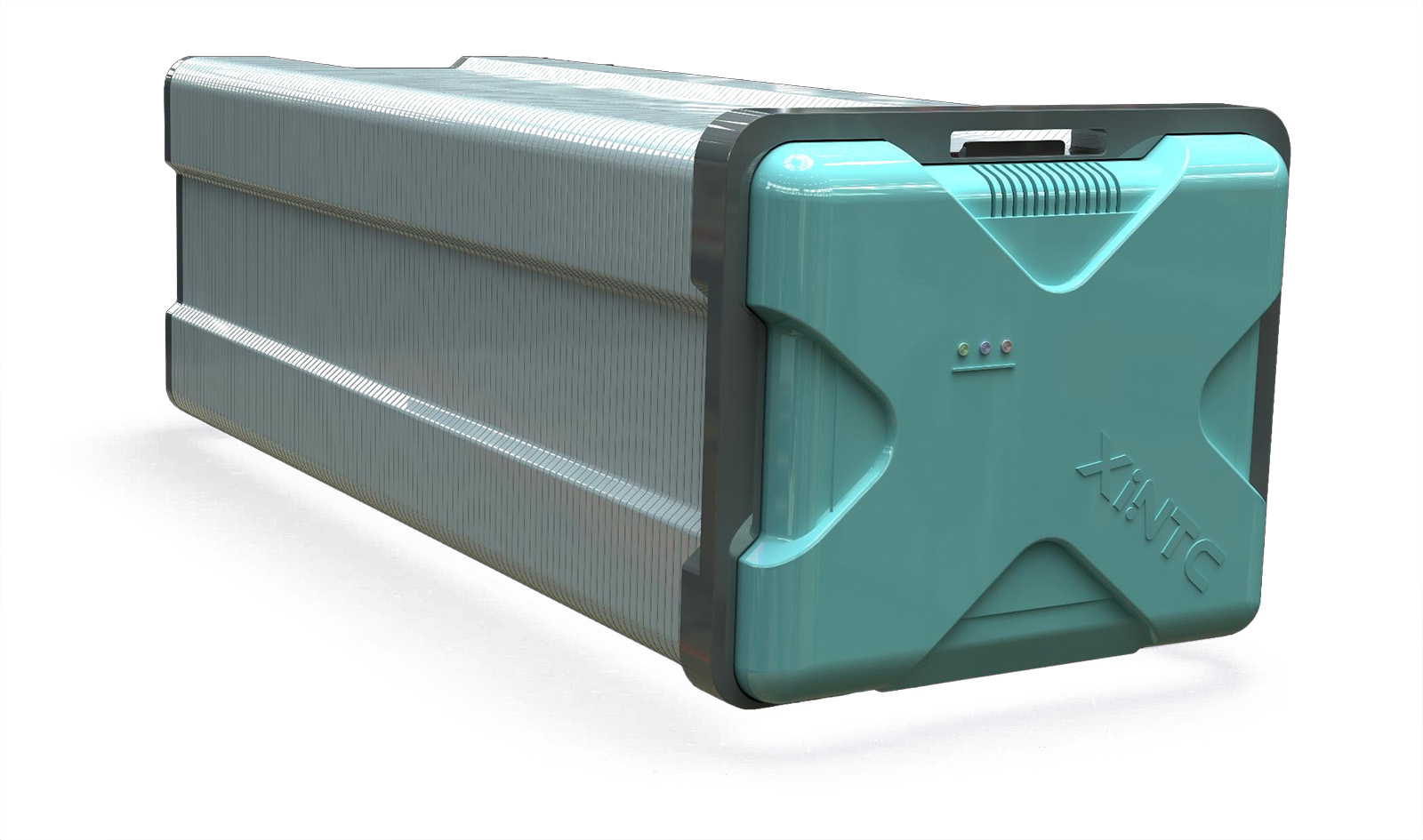

Each gas module accomplishes an individual task,

all gas modules together deliver a collective performance.

5 – 6.5 kW gas module

Due to the use of technical plastics and a sophisticated mounting technique, the electrolyser module has a long service life and high intrinsic safety. Gas modules operate in pairs and each set is equipped with embedded electronics for optimum process control and monitoring. De facto, each individual module works at its best possible operating point in terms of gas production and efficiency, regardless of the load.

Modern design

Plastic enclosure

Fluid & gas tight

Recyclable

Embedded software

No gaskets

No critical materials

No membranes

Complying with international technical standards

5 – 6.5 kW

gas module

gas module

Due to the use of technical plastics and a sophisticated mounting technique, the electrolyser module has a long service life and high intrinsic safety. Gas modules operate in pairs and each set is equipped with embedded electronics for optimum process control and monitoring. De facto, each individual module works at its best possible operating point in terms of gas production and efficiency, regardless of the load.

Modern design

Plastic enclosure

Fluid & gas tight

Recyclable

Embedded software

No gaskets

No critical materials

No membranes

Complying with international technical standards

Each gas module accomplishes an individual task, all gas modules together deliver a collective performance.

WIND

SOLAR

GRID

The ultimate link between (multiple) power sources and hydrogen consumers

BUILT ENVIRONMENT

Power to Gas skids

Electrolyser

Compression

Mixing

MOBILITY

ECSD skids

Electrolyser

Compression

Storage

Dispensing

INDUSTRY

Power to Gas skids

Electrolyser

Compression

Storage

GAS TURBINE

Gas to Power skids

Electrolyser

Storage

Gasturbine

FUEL CELL

Gas to Power skids

Electrolyser

Storage

Fuel cell

WIND

SOLAR

GRID

The ultimate link between (multiple) power sources and hydrogen consumers

BUILT ENVIRONMENT

Power to Gas skids

Electrolyser

Compression

Mixing

MOBILITY

ECSD skids

Electrolyser

Compression

Storage

Dispensing

INDUSTRY

Power to Gas skids

Electrolyser

Compression

Storage

GAS TURBINE

Gas to Power skids

Electrolyser

Storage

Gasturbine

FUEL CELL

Gas to Power skids

Electrolyser

Storage

Fuel cell

System Section

A modular approach, conceived to scale with evolving business practices

The Balance of Plant includes all peripheral equipment and piping systems which, together with the gas modules, constitute the electrolyser installation. All BOP components are standard (dedicated) modules and scale with production capacity expansion. The output pressure is adjustable between 1 bar and 10 bar, the hydrogen quality between class 2.5 and 5.0.

30 gas modules together form a System Section. Within the contour of a System Section, the installed nominal power can be up to nominal 150 kW and 200 kW short-term peak power. Each section is powered by its own power supply station.

A modular approach, conceived to scale with evolving business practices

System Section

The Balance of Plant includes all peripheral equipment and piping systems which, together with the gas modules, constitute the electrolyser installation. All BOP components are standard (dedicated) modules and scale with production capacity expansion. The output pressure is adjustable between 1 bar and 10 bar, the hydrogen quality between class 2.5 and 5.0.

30 gas modules together form a System Section. Within the contour of a System Section, the installed nominal power can be up to nominal 150 kW and 200 kW short-term peak power. Each section is powered by its own power supply station.

XINTC capacity enlargement

XINTC’s modular approach is ideal to serve smaller and larger production capacity demands and to adapt seamlessly to business progression. Interchangeable standardized gas modules to cover the requested capacity with incremental steps. Hydrogen production capacity can be enlarged at any time.

XINTC capacity enlargement

XINTC’s modular approach is ideal to serve smaller and larger production capacity demands and to adapt seamlessly to business progression. Interchangeable standardized gas modules to cover the requested capacity with incremental steps. Hydrogen production capacity can be enlarged at any time.

XINTC electrolysers produce

hydrogen in 2.5 grade to 5.0 grade

and from atmospheric pressure

up to 350 bar by linking

function-specific process modules

XINTC electrolysers produce

hydrogen in 2.5 grade to

5.0 grade and from

atmospheric pressure

up to 350 bar by

linking function-specific

process modules

XINTC electrolysers come as containerized units

All XINTC electrolysers come as high cube compartmentalized containerized units

Each production enclosure accommodates up to 8 system sections, accumulating to 1.2 MW nominal capacity and 1.6 MW peak.

XINTC provides maximum flexibility in terms of capacity, pressure and gas purity. The standard configuration comprises a Power & Control Module followed by a Gas Production Module. These linked units produce hydrogen in 99,5% purity and 0.5 bar pressure. For applications that require a higher output pressure and a higher purity, a Compression & Purification Module is added.

XINTC electrolysers come

as containerized units

All XINTC electrolysers come as high cube compartmentalized containerized units

Each production enclosure accommodates up to 8 system sections, accumulating to 1.2 MW nominal capacity and 1.6 MW peak.

XINTC provides maximum flexibility in terms of capacity, pressure and gas purity. The standard configuration comprises a Power & Control Module followed by a Gas Production Module. These linked units produce hydrogen in 99,5% purity and 0.5 bar pressure. For applications that require a higher output pressure and a higher purity, a Compression & Purification Module is added.

The concept of XINTC is based on sustainable and responsible use of materials and the principle of good enough design

Minimizing the impact of variation

Performances insensitive to ambient use conditions

Low material and components degradation over time

Built to last

Controlled production process

Fit for purpose; no frills

The concept of XINTC is based on sustainable and responsible use of materials and the principle of good design

Minimizing the impact of variation

Performances insensitive to ambient use conditions

Low material and components degradation over time

Built to last

Controlled production process

Fit for purpose; no frills

XINTC has clear cost advantages and capability to further decrease LCOH, both in OPEX and in CAPEX

XINTC has clear cost advantages and capability to further decrease LCOH, both in OPEX and in CAPEX

XINTC allows direct coupling with intermittent power sources and are fully equipped for dynamic operation

Up to 20% efficiency gain with solar power

XINTC allows direct coupling with intermittent power sources and are fully equipped for dynamic operation

Up to 20% efficiency gain with solar power

Local production

Small-scale production of hydrogen with local consumption using solar and wind energy and surplus network capacity will likely accelerate the market growth towards net zero carbon emission.

Local production

Small-scale production of hydrogen with local consumption using solar and wind energy and surplus network capacity will likely accelerate the market growth towards net zero carbon emission.